Metal detectors are required in many industries, like security, and they can provide hours of

recreational entertainment as a pastime. Each metal detector must be calibrated to be sensitive to

the kind of material that the machine needs to detect.

Metal detector calibration is a process that sets the metal detector to a specific sensitivity.

Depending on the intended use of the metal detector, different sensitivities must be

achieved for each machine to detect the desired size and type of metal or metal

contaminant.

Each detector must be calibrated differently, and it is good to know the different processes of

calibration, validation, and audit for each machine. It is crucial that the metal detector’s

sensitivity be correct for certain industries, like food preparation, pharmaceuticals, and textile

production.

What Is Metal Detector Calibration?

Metal detector calibration is, quite simply, the process of setting a metal detector to the desired

sensitivity. The sensitivity of a metal detector determines the machine’s ability to detect specific

types and sizes of metals.

The different purposes and environments that metal detectors operate in require calibration to

different sensitivities and to discriminate between metals. The size of the metal that a metal

detector will react to is determined by sensitivity. Most recreational metal detectors also have

discrimination settings that determine the types of metals to which it will react.

Other settings, like depth control and discrimination, are built into high-end recreational metal

detectors. These settings are pre-loaded so that, with the push of a button, the user can decide

which kinds of metals to which they want the detector to react to.

Another common setting on recreational metal detectors is for environmental factors. Many

recreational detectors will have settings that discriminate between iron-heavy soil, salty beaches,

and other environments.

These settings are designed to be simple to use and are accessible through the user interface of

the metal detector. Simply choose the environment into which you are taking the detector, and

the machine will discriminate for that kind of soil or environment.

Understanding Metal Detector Sensitivity

The higher the sensitivity, the smaller the pieces of metal a metal detector will detect. Detectors

can pick up ferrous, non-ferrous, aluminum, or stainless steel. Most detectors can be calibrated to

detect (or ignore) those types of metals.

Ferrous metals are the easiest to detect and, with high sensitivity, most machines will be able to

detect very small pieces of ferrous metals. Ferrous metals are generally magnetic and, since

metal detectors react to the magnetic field of metal, they are easier for the machine to detect.

Stainless steel is the most difficult to detect, and, as such, if you are trying to detect stainless

steel, you might need to calibrate the detector to very high sensitivity.

Generally, a metal detector’s sensitivity is determined by its ability to detect metal of a certain

diameter. Small changes in sensitivity can have a big impact on the size of metal pieces or

contaminants that a metal detector can detect.

Metal detectors that are used in industrial and security settings usually have high sensitivity so

that their alarms will sound when even the smallest piece of metal passes through.

Understanding Metal Detector Discrimination

So what is discrimination in metal detecting?

Discrimination settings on metal detectors let the user or operator decide which metals to which

the detector reacts. Often, users will have good reason to set the metal detector to discriminate

for iron or aluminum so that those common metals aren’t found.

In industrial settings, metal detectors will sometimes need only to find a certain kind of metal

that is present in the work environment so that quality control workers can be sure that those

metals are not present in the products as before they are shipped out.

If an industry needs a metal detector to discriminate for certain metals, they will ask the

the manufacturer or the company that services their detector to set those discrimination parameters.

Walk-through metal detectors that are used for security are not calibrated to discriminate for

certain metals because the purposes of those are to detect any metal on the person that passes

through the detector.

Many recreational metal detectors also have easy-to-use discrimination settings. With a few

button clicks on the user interface, users can set the metal detector to discriminate for certain

metals. This is a handy feature in iron-rich areas to eliminate noise and chatter from the detector

and allow the user to find more valuable metals.

Other Calibration Factors

In addition to sensitivity and discrimination, the orientation of a metal detector will determine its

ability to detect a non-spherical piece of metal, such as a wire. The spherical diameter of wire

might be smaller than the detector’s sensitivity can detect, in some cases, and the orientation

effect can give the detector the ability to pick up on such pieces of metal.

If you are looking to install an industrial metal detector into your production facility, the

company that sells you the detector will calibrate the detector to your desired specifications.

They will work with you to ensure that the kinds, sizes, and shapes of metal that you need to

detect are picked up by the metal detector and activate the detector’s alarm.

There are different environmental factors that can also affect the detector’s performance. Some

recreational metal detectors have pre-loaded modes that can help to reduce the noise of a salty

beach or other environments, while factory metal detectors will have noise and vibration

immunity built-in to minimize the risk of electrical interference.

If you plan to use your metal detector on a salty beach or are aware that there is a lot of iron in

the area you will be using the metal detector, do research to make sure you buy a metal detector

that has features that allow you to calibrate and discriminate for those environmental factors.

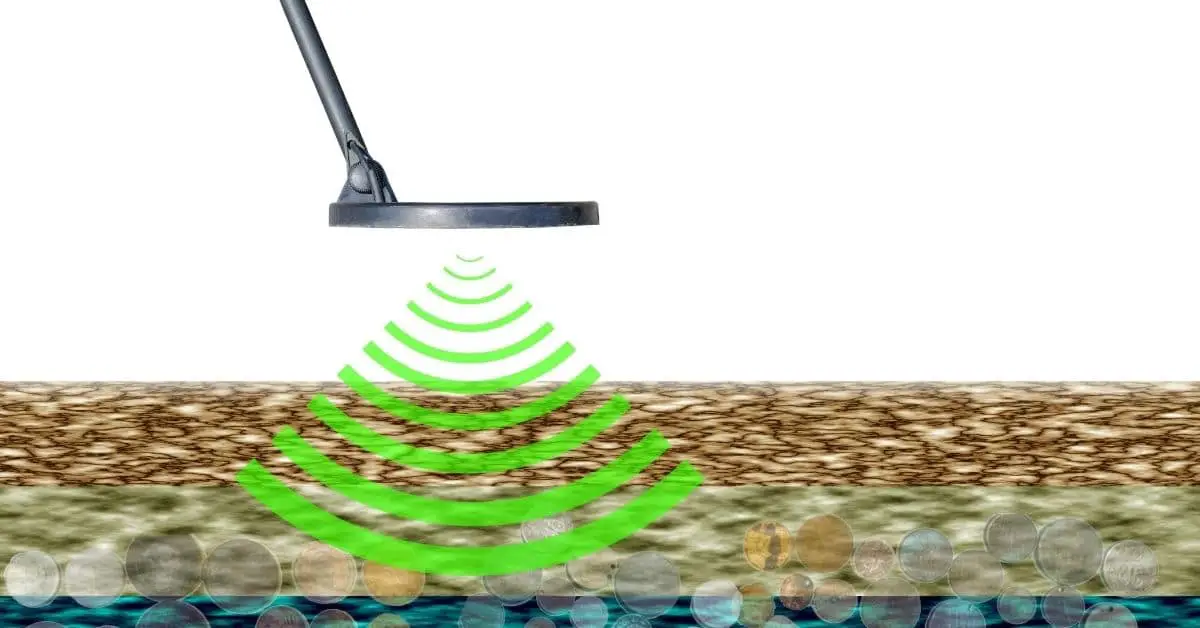

How Metal Detectors Work

There are all different sorts of metal detectors for industrial use, security, and personal

recreational use, but they all operate using the same basic principles. Understanding how metal

detectors work will help you to know how to calibrate them and why calibration is important.

Every metal detector has a single coil or a set of coils. Those coils use electromagnetic induction

to detect the presence of metal. They produce an electromagnetic field that causes the metal

detector to sound an alarm when in contact with the magnetic field produced by metals.

This is how metal detectors can determine what type of metal it is detecting. Each metal’s

electromagnetic field is different, so metal detectors are programmed to recognize specific fields

as specific metals. A metal’s electromagnetic field is like a signature that is specific to that metal

or alloy.

Sensitivity settings increase or reduce the size of the magnetic field to which the detector will

react. Discrimination settings allow certain electromagnetic signatures to pass through without

alarm while it will react to others.

Large metal detectors, like those insecurity or food processing, are operated by a microchip that

is programmed for sensitivity, orientation, and discrimination. Recreational metal detectors are

also operated by microchips, but the user interface of each detector allows users to change the

programing whenever the need arises.

Digging Deeper: How Metal Detectors Work – A Comprehensive Guide

Industrial Metal Detectors

Metal detectors are common in many industries, such as wood processing, biofuel, recycling, and

aggregate industries. Corporations like Metal Detectors Inc. produce and service high-quality

metal detectors for industrial use.

Large industrial metal detectors are operated by a microchip that is programmed for sensitivity,

discrimination, and orientation. This is why it is almost always required to have a specialized

technician calibrate and validate industrial detectors.

Laborers in these industries will not be expected to calibrate these metal detectors. It is more

likely that a service technician from the company that produced the metal detector will calibrate

the metal detector to the desired discrimination and sensitivity when the detector is installed.

Corporations like Metal Detectors Inc. also offer servicing for their products. They will visit the

factory or production location regularly to service, repair, calibrate, and validate the metal

detectors that they produce. They utilize standards of pure metals at different sizes to validate

that the sensitivity and discrimination settings are working as required by the factory setting.

Examples of industrial metal detectors include those that sit atop conveyor belts. These are used

in the aggregate industry to ensure that only the materials that are desired are passing through the

detector and give laborers the ability to easily locate and pick out unwanted metals.

Wood mills also use large metal detectors to make sure that only wood is passing through.

Sometimes, large trees have metal shards in them that need to be removed before that wood can

be processed.

Securities Metal Detectors

Anyone who has been through an airport is familiar with the large, walk-through metal detectors

that securities professionals utilize. These metal detectors are set to high sensitivity. You may

have noticed that they will pick up the smallest bit of metal, like earrings and other jewelry.

Most metal detectors rely on a single coil; walk-through metal detectors utilize two coils. A

current is sent through both coils through a process called pulse induction. The two coils send

pulses of electrical current between each other.

Each pulse lasts only about 30 microseconds, and walk-through detectors can emit hundreds of

pulses every second. When the pulse interacts with a metal of any kind, it detects the magnetic

field and the alarm on the detector sounds.

Protective Technologies International is one corporation that produces and services metal

detectors. They calibrate these detectors to high sensitivity and no discrimination so that any

metal on a person will be detected.

Many securities metal detectors now operate with digital technology, which allows the company

that produced the detector to constantly monitor and adjust the detector’s settings via an internet

connection. This ensures that, in a most crucial environment, the metal detectors are always

operating as they should.

Why Calibration Is Important

Whether using a metal detector for recreation or industrial purposes, calibration is important in

order to set the metal detector up to successfully detect the desired size of metal or type of metal.

Industrial

Proper calibration is crucial for industrial metal detectors and, while the manufacturer will

typically service and calibrate the detector for the client, it can be useful to know about how

sensitivity affects what will be detected.

Since foods and other goods are manufactured and produced using automated machinery, it is

possible that metal shavings or other machine parts get mixed up in the product. Proper

calibration is especially important for industrial applications of metal detectors in food

preparation and other factory production to ensure that no metal contaminants are present in the

product.

Regular calibration is important for all industries where metal detectors are used daily. If a metal

detector is malfunctioning and metal slips through undetected, it can cause costly damage to

machinery or unwanted metal might be shipped out with products.

Certain packaging materials and product characteristics can affect the sensitivity, and necessary

calibration, of a metal detector. It is important that industrial detectors are calibrated to the

proper specification so that the type and size of the metal contaminant in products are accurately

detected.

Security

Metal detector calibration is important in security settings for the alarm to sound if anyone tries

to enter a building or airplane with metal that is not allowed. For instance, metal detectors are

placed at the front of many government buildings so that no one can bring a weapon or other

dangerous metal object into the building.

Airports security requires a metal detector to ensure that no one is hiding anything dangerous

underneath close or elsewhere. These walk-through security metal detectors are calibrated to a

high degree of sensitivity so that the alarm sounds when even the smallest bits of metal is

passed through.

Additionally, schools now often have metal detectors at some entrances so that students and

visitors cannot enter the building with weapons or other dangerous metal objects. Calibration is

crucial in these environments so that everyone in the building is kept safe.

Recreational

Recreational metal detectors will usually have simple, straightforward sensitivity controls that

allow you to adjust the sensitivity and, consequently, the size of metal the detector will detect.

They will also sometimes allow users to eliminate the detection of certain kinds of metal or

automatically calibrate for certain environmental factors.

It is important to set follow the steps below to adjust the sensitivity of the metal detector so that

it sits in the right range to pick up on metals without producing excess noise. Many metal

detectors also have pre-loaded settings for discrimination. They might also have settings that

calibrate the metal detector for saltwater beaches, dense clay soil, and iron-heavy soil.

Since each model of metal detector is different, it is important to read the manual for your

detector to determine how you can access each of the settings for your detector.

The Difference Between Calibration, Validation, and Audits

While calibration sets the sensitivity for the size and types of metals to which a metal detector

reacts, validation and audits are designed to test that calibration. Validation is conducted

regularly in industrial or security settings in order to ensure that the metal detector is still

properly calibrated.

Validation and audits are conducted every day with industrial and securities metal detectors.

Each time the detector reacts to metal, that is a validation that the machine is still working

properly.

For recreational metal detectors, you can validate that the detector is working properly by setting

metals of different kinds on the ground and making sure that the user interface recognizes it as

the right type of metal. Adjusting sensitivity will determine the size of metal objects it picks up.

Recreational users can also validate that the discrimination settings on their detectors are

working properly by setting the detector to discriminate against something like iron and then

passing the detector slowly over a piece of iron to see if the detector reacts.

Calibrating Industrial & Securities Metal Detectors

As mentioned above, the corporations that produce metal detectors for industrial or securities

uses will perform an initial calibration. Those companies also usually offer servicing for the

machines that they produce.

Every metal detector is different. There are detectors that are designed for specific use in the

food production industry, textile manufacturing, milling, and many others. Walk-through metal

detectors are designed for securities applications.

The companies that service metal detectors will know how to access the control panel for each

machine. They will probably also have a device that is connected to the control panel that allows

sensitivity, discrimination, and orientation to be adjusted.

Before being sold to industries, metal detectors are calibrated and validated with cards of specific

types of metal. The process is rigorous to ensure that the detector was produced in the right way

and that it will function properly once it gets to the location where it will be used.

Factories that have a lot of different metal detectors for different conveyor belts or assembly

lines might hire a specialized metal detector technician to make sure that all of their detectors

function properly every day.

How To Calibrate A Recreational Metal Detector

Metal detectors that are put to use in industrial or securities settings are typically calibrated by

professionals and is often a service provided by the manufacturer that produced and sold each

detector. Calibration for recreational detectors can be conducted at home through a number of

steps and is different for each metal detector.

To calibrate a recreational metal detector, you will first want to become familiar with the settings

of that metal detector. If you have the manual that came with the detector, read that to understand

the different settings of your device.

Many recreational metal detector manufacturers also make their manuals available online, so you

might search for the manual that corresponds to the make and model of the metal detector that

you own if you don’t have access to the physical manual.

There are two standard functions of recreational metal detector calibration: sensitivity and

discrimination. Sensitivity, as mentioned above, controls the size of metals that will be detected,

and discrimination determines the types of metals that can be detected.

Some recreational detectors also have pre-loaded settings that allow the owner to calibrate for

certain environmental factors that might interfere with the detector’s performance. For example,

the saltwater on beaches can interfere with a metal detector and produce a lot of noise, but some

recreational detectors have settings that allow the detector to function as normal on a saltwater

beach.

Digging Deeper: Are Hobby Metal Detectors Safe?

Calibrating Recreational Metal Detectors

The goal of calibration is to find the narrow window of sensitivity that will allow you to detect

the metal properly without producing excess noise and chatter. Most metal detectors take large

batteries, such as 9-volt batteries, for power.

Before conducting a calibration routine, power the detector up and let it warm up for 5-10

minutes. This will ensure that the coil is operating at full capacity before you attempt a

calibration.

The basic calibration and validation method for recreational metal detectors is as follows:

ï‚· Find a large, flat area in your yard or driveway. Use the metal detector to search that area

and make sure no targets or contaminants are there. If they are, remove the source of

interference or find a different spot.

ï‚· Place a coin of each type and a piece of jewelry or other metal on the ground and use the

metal detector to see how it reacts. Proper detection requires slow, methodical

movements.

ï‚· You can determine the depth at which the metal detector will react by moving the coil

away from the objects. This isn’t quite accurate, but it will give you a general idea. The

detector will work better when objects are buried.

ï‚· Adjust the sensitivity and discrimination until the metal detector registers the proper type

of metal for each object.

ï‚· Repeat the process until the metal detector accurately detects each coin or type of metal.

Calibration and subsequent validation should be completed before each time you go out with the

metal detector to ensure that the detector is functioning properly. Make sure to adjust the

sensitivity and discrimination for the types of metals for which you are searching and for any

environmental factors that could affect the detector’s calibration.

Recreational Metal Detector Brands

There are dozens of different kinds of recreational metal detectors produced by different

manufacturers. Each detector will have different settings, and that will determine the approach to

calibration that is necessary. These are the top-rated metal detectors from Amazon reviews.

Garrett Ace 300 & 400

Both of these models from Garrett Metal Detectors have high reviews and provide easy

calibration. The 300-level model has only four sensitivity levels, while the 400-level model

doubles that with eight sensitivity levels and depth adjustment.

Additionally, both of these models have five search modes that discriminate between the types of

metals or objects that you hope to find. The main difference between the models is the level of

sensitivity adjustment possible and the size of the search coil.

Digging Deeper: Garrett Ace 300 Review (2020) – Extras Included

Fisher F75

The Fisher F75 line of metal detectors is an affordable favorite. The discrimination accuracy of

these detectors is great for iron-heavy areas and can easily filter out the noise of unwanted

targets. The Digital Shielding Technology that these Fisher models offer reduces electromagnetic

interference and unwanted signals with minimum calibration.

The base frequency at which the Fisher F75 operates is 13 kHz, which will find a wide variety of

targets. This model also has frequency shifting available, which allows for slight changes and

more in-depth calibration options.

Bounty Hunter Tracker IV

The Tracker IV model from Bounty Hunter metal detectors has great sensitivity and

discrimination controls at an affordable price. The tracker is beloved for its ground balancing

capability, which allows it to operate well with any type of sand or soil.

This metal detector has a rugged design that is good for all conditions and can detect larger

objects at up to 3ft depths. It features an 8in coil and operates at a 6.7 kHz frequency.

Teknetics EuroTek Pro

Boasting ultimate calibration control at an affordable price, the EuroTek Pro from Teknetics is

affordable has an impressive battery life for hours of detecting between charges and offers

superior distinction settings for iron.

This model operates at 7.8 kHz and has an 8-inch coil. The 10-level sensitivity settings and a

wide range of discrimination adjustments allows the user to be in control of the experience.

Conclusion – Metal Detector Calibration

So there you have it metal detector calibration. How to do it and why it is important. I hope I provided you with enough information that you were looking for. If you have any questions or comments please leave them below. Thanks for reading and Happy Treasure Hunting!

Thank you. This was very helpful. I’m just getting into metal detectors.

You are very welcome Dennis! You can also check out my Beginners Guide to Metal Detecting for more helpful tips and information on getting started in the metal detecting hobby. Happy treasure hunting!